melt flow index test procedure|melt flow index formula : Brand Melt Flow Index testers, also known as Melt Flow testers, are essential in measuring the flow rates of thermoplastic polymers. These instruments calculate how much . Resultado da delfinasuarèz | 266.1M views. Watch the latest videos about #delfinasuarèz on TikTok.

{plog:ftitle_list}

Ultra-fast high-speed fibre home Internet. Command the fastest upload speeds with Bell Fibe Internet on Canada’s largest fibre optic network. Bell's high-speed home Internet lets you share photos and videos with upload speeds of up to 940 Mbps and download .

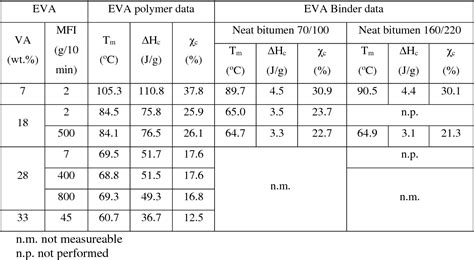

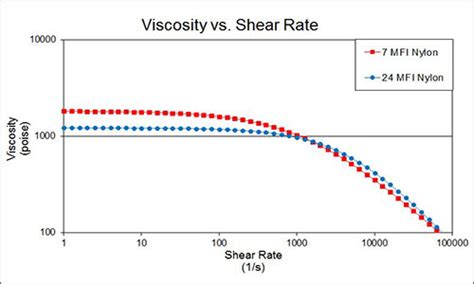

The melt flow index (MFI) or melt flow rate (MFR) is a measurement used to assess the flowability or melt viscosity of a polymer. It provides an indication of how easily a polymer can be processed through different processes. Melt Flow Index testers, also known as Melt Flow testers, are essential in measuring the flow rates of thermoplastic polymers. These instruments calculate how much .

This is where the Melt Flow Index (MFI) Tester comes into play, allowing you to evaluate the flow properties of polymers accurately. In this blog, we'll delve into the importance of MFI testing, its applications, and how to use . When it comes to determining MFI, there is no one-size-fits-all approach. Several testing approaches exist, with ASTM D1238 and ISO1133 being prominent methods. This standard is widely accepted and adopted for .1.0 INTRODUCTION TO MELT FLOW INDEXING 1.1 MELT FLOW RATE The melt flow rate (MFR) of a thermoplastic material is the measured gravimetric flow of the sample extruded .The procedure for determining MFI is as follows: A small amount of the polymer sample (around 4 to 5 grams) is taken in the specially designed MFI apparatus. A die with an opening of .

Melt Flow Index is a test that is used to determine the average molecular weight of a thermoplastic polymer. The Melt Flow Index test is performed by heating a sample of the .

1.0 INTRODUCTION TO MELT FLOW INDEXING 1.1 MELT FLOW RATE The melt flow rate (MFR) of a thermoplastic material is the measured gravimetric flow of the sample extruded .

The Melt Flow Index (MFI) refers to a characteristic used to assess the quality and flow properties of polymers. It measures the amount of material that can be deposited through a .The ISO 1133-1 standard establishes the general test method for determination of melt mass-flow rates (MFR) and melt volume-flow rates (MVR) of thermoplastics. Part 2 of ISO 1133 (ISO 1133-2) describes the method for .Melt flow testing is a test method used to determine the flow properties of thermoplastic materials. The test measures how much material flows through a standardized die while subjected to a specified load and temperature. The .

The melt flow index measurement is a standardized test method to characterize the flowability of plastics at a defined temperature and constant force with a plastometer. . When determining the melt flow rate (MFR) according to procedure A, the extruded material strand is cut off at constant time intervals. Using a laboratory balance, the . The Melt Flow Index test originated in the labo- ratories of ICI, . of test procedures to cover a number . of . different ther- moplastics. The ASTM D1238 (1979y and DIN 53735

The Melt Flow Index test is performed by heating a sample of the polymer to a specific temperature and measuring the time it takes for the polymer to flow through a small opening. The Melt Flow Index is inversely proportional to the average molecular weight of the polymer; therefore, a high Melt Flow Index indicates a low average molecular .

Melt Flow Rate (MFR) or Melt Flow Index (MFI) is the flow measurement of polyethylene being pushed through a 2mm diameter die at 190°C with 2.16 kg mass. The result is expressed in grams per 10 minutes (g/10 min). Experimental Procedure Summary Approximately 6 to10 grams of polyethylene is loaded into the barrel of the melt flow plastometer . Rather, the melt flow index is an empirical value that is ultimately influenced by the conditions of the test. This article discusses the importance of MFI and delves into the intricacies of MFI, measurement techniques, and relevance in the polymer industry, all while highlighting its significance.

The MP1200 is available in two distinct versions: the manual MP1200 and the motorized MP1200M. The manual MP1200 comes with everything you need - except weights and laboratory balance - to perform an ASTM D1238 Procedure A (manual cut) gravimetric melt flow rate (MFR). Test loads are applied manually.The basic version of the mi40 plastometer can perform MFR or MVR measurements according to ISO 1133 Procedure B and ASTM D1238 Procedure B. Multi-weight-measurements to calculate the FRR (Flow Rate Ratio) according to ASTM D1238 Procedure D are also possible. . The melt flow index is a standardized test method to determine the flow rate of .

1.0 INTRODUCTION TO MELT FLOW INDEXING 1.1 MELT FLOW RATE The melt flow rate (MFR) of a thermoplastic material is the measured gravimetric flow of the sample extruded through a die following specified conditions of die length, diameter, tem-perature and pressure. Different standardised conditions of extrusion temperatures and pres-The methods for melt flow index testing to ASTM D1238 and ISO 1133 on thermoplastics are equivalent but not identical, as they differ in some respects, especially in terms of test procedure: For some polymers, test temperatures and test weights are specified differently in .

plastic melt flow index chart

It is generally used for materials having melt flow rates that fall between 0.15 and 50 g/10 min (see Note 1). 1.3 Procedure B is an automatically timed measurement used to determine the melt flow rate (MFR) as well as the melt volume rate (MVR) of thermoplastic materials. MFR measurements made with Procedure B are reported in g/10 minutes.Using standard test procedure and conditions to perform MFI test on plastic granules is the best way to determine the physical as well as chemical properties of the material. Presto Stantest understands the need for measuring MFI of polymer granules and offers a high-quality Melt Flow Index Tester. The testing instrument is ergonomically . ASTM D1238 and ISO 1133 are the most common standards for melt flow tests, as they define both equipment specifications and test methods. Test parameters are always reported with the results, because various weights and temperatures are suggested for .ISO 1133 – Determination of Melt Mass Flow Rate (MFR) and Melt Volume Flow Rate (MVR) of Thermoplastics ISO 1133 was updated in 2011 – it now specifies tighter tolerances on the temperature in the cylinder and on the time duration over which the material is subjected to that temperature. Some older models of MFI units no longer comply with .

Temperature: The temperature at which the test is conducted significantly affects the MFI. Higher temperatures reduce viscosity and increase the MFI. Pressure: The applied pressure . Standard Testing Procedures .The Instron® Melt Flow Testers are specifically designed for easy and accurate measuring of the Melt Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate (MVR). CEAST Melt Flow Testers range from systems that perform a simple manual test procedure to semi-automated testing systems performing multiple weight tests.The melt flow test (also referred to as melt index test or melt flow index test) is a test method used to determine the flow properties of thermoplastic materials. . in the methods for MVR and MFR determination on thermoplastics according to ISO 1133 and ASTM D1238 lies in the test procedure and the test conditions: Test temperatures and test .as a “Flow Rate Ratio” (FRR) test. Procedure D is designed to allow MFR determinations to be made using two or three different test loads (either increasing or decreasing the load during the test) on one charge of material. The FRR is a . (Alternative Names—Melt Indexer, .

The MFi5 is a compact instrument that allows rapid inspection of the melt mass flow rate of plastics to Method A, Method B and Method C. It is especially designed for different needs, from simple Incoming Material Acceptance to Process Control checks. The manually operated MFi5 tests plastics quickly and reliably thanks to the pre-set methods.1.0 INTRODUCTION TO MELT FLOW INDEXING 1.1 MELT FLOW RATE The melt flow rate (MFR) of a thermoplastic material is the measured gravimetric flow of the sample extruded through a die following specified conditions of die length, diameter, tem-perature and pressure. Different standardised conditions of extrusion temperatures and pres-You can calculate the melt index flow with the help of the melt index flow formula. This testing instrument will be helpful in checking the quality of materials used in finished products. Here are several things that you are likely to get with the MIF test. It will be helpful in calculating the typical index value for verifying in-house material.

v20 volumetric karl fischer titrator commercial

The modular GÖTTFERT mi-2 series melt flow indexer allows users to upgrade from a manual operated entry-level unit to a semi-automatic machine. ASTM D1238; ISO 1133; . Test procedure: Automatic measurement with single load: Automatic measurement with single load and manual weight selection: Test chamber:The MFi7 is a melt flow index tester for a growing volume of Procedure A, Procedure B and Procedure C tests. Designed to increase production speed, it offers high level of accuracy and shorter cycle times overcoming manually powered limits thanks to fatigue-free motorized cleaning and automatic material compacting and purging.FAQ MP1200 Melt Flow Tester running procedure B test | Tinius Olsen

A flow rate test is a measure of a polymer’s mass flow rate (grams extruded in 10 minutes) using an orifice under specified conditions of temperature and load. Machines that determine flow rate are generally called Melt Indexers or Extrusion Plastometers . Test methods by ISO, DIN, ASTM and others specify heat chamber and The melt flow index (MFI), also known as the melt flow rate (MFR), determines the melt flow properties (measured in g/10 min) of a material at a specific shear stress (related to applied load) and temperature. . As with Procedure A, the first measurement of a Procedure B test is considered to be the reportable test result. However, many .

volumetric karl fischer titration astm commercial

Resultado da Há 20 horas RBS Notícias Inter estreia na Copa do Brasil enquanto Grêmio decide Recopa Gaúcha Equipes gaúchas disputam outras competições .

melt flow index test procedure|melt flow index formula